Packaging industry

- Home

- Blog Archive

- Packaging

- Jolin Z.

- May 26, 2024

How Digital Oscillating Knife Cutters Revolutionize Packaging & Corrugated Box Production

Digital oscillating knife cutters are transforming the packaging industry. These advanced machines are changing how corrugated boxes are produced.

They offer precision and flexibility that traditional methods can’t match. This technology is a game-changer for manufacturers.

The demand for customized packaging is growing. Digital oscillating knife cutters meet this need efficiently.

In this article, we explore how these machines revolutionize corrugated box production. Discover their benefits and applications in the packaging industry.

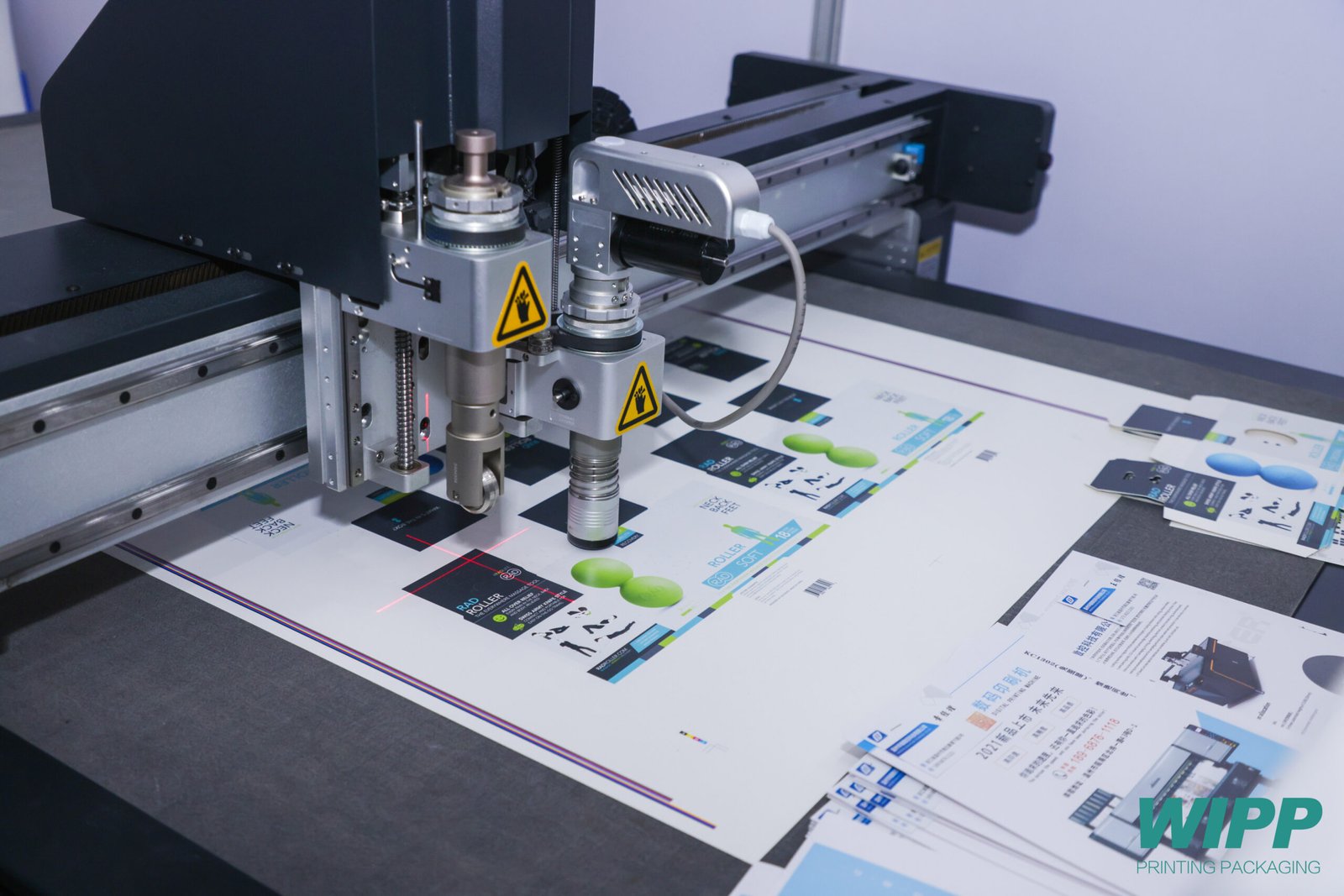

Understanding Digital Oscillating Knife Cutters

Digital oscillating knife cutters are precision tools used in the packaging industry. They utilize a rapidly moving blade to create precise cuts. This feature is essential for delicate and custom designs.

These cutters operate by combining speed with accuracy. Advanced software facilitates seamless design modifications. This capability enables quick prototyping and efficient production.

There are key characteristics that set digital oscillating knife cutters apart:

- Versatility: Suitable for a range of materials beyond cardboard.

- Precision: Ensures high-quality cuts for complex designs.

- User-Friendly: Minimal training needed for operation.

Moreover, these cutters are equipped with digital technology. They are compatible with various design software, which simplifies integration into existing workflows.

Overall, digital oscillating knife cutters offer a modern solution for today’s packaging demands. They empower businesses to innovate and improve production quality.

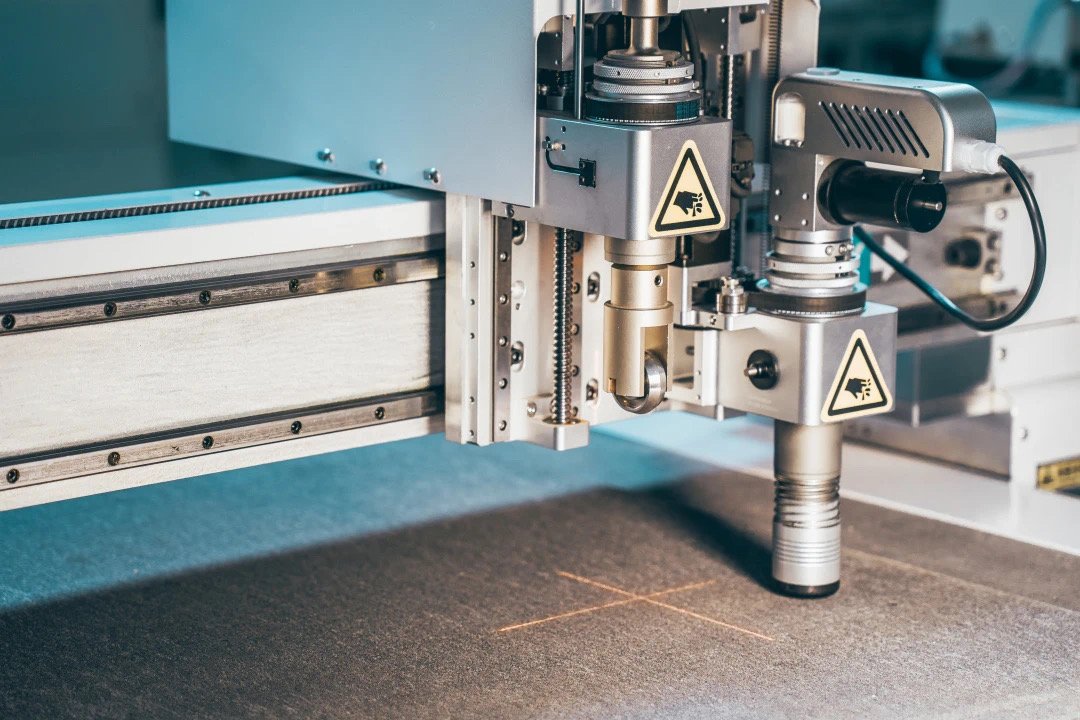

How Digital Oscillating Knife Cutters Work

Digital oscillating knife cutters utilize a unique cutting mechanism. This involves a blade that oscillates at high speed. The rapid motion allows for precise and clean cuts through various materials.

The operation is guided by advanced software. This software interprets design files to execute precise movements. As a result, the machine adapts to complex patterns with ease.

Key components of digital oscillating knife cutters include:

- Oscillating Blade: Provides fast, clean, and accurate cuts.

- Digital Interface: Simplifies design input and adjustments.

- Motor System: Ensures consistent blade movement for uniform cuts.

By efficiently combining these elements, digital oscillating knife cutters transform packaging production. They simplify the manufacturing process while enhancing the final product’s quality.

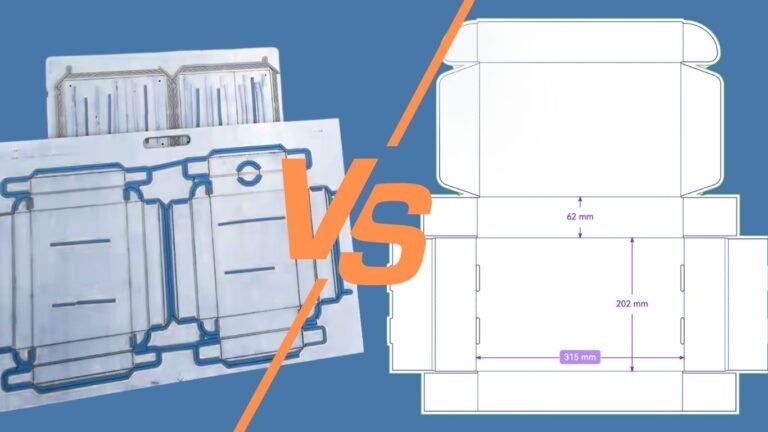

Key Advantages Over Traditional Cutting Methods

Digital oscillating knife cutters offer several advantages over traditional die-cutting methods. One key benefit is their precision. These machines deliver sharp, exact cuts that enhance packaging integrity and visual appeal.

Time efficiency is another major advantage. With minimal setup time, digital cutters streamline production processes. This efficiency enables manufacturers to handle urgent orders and adapt to fast-paced market demands.

Another advantage is versatility. Digital cutters can manage a wide array of materials. This includes corrugated cardboard, foam, and rubber, making them a versatile tool in packaging.

Cost savings are significant with digital cutting machines. They reduce material wastage and labor costs, providing economic benefits to companies. Here are the standout benefits:

- Precision Cuts: Ensures high-quality results.

- Time Efficiency: Reduces setup time and increases output.

- Versatility: Suitable for various materials.

- Cost Savings: Minimizes waste and labor expenses.

By offering these advantages, digital oscillating knife cutters revolutionize the packaging industry. They align with current needs for flexible and efficient production solutions.

Applications in Corrugated Box Production

Digital oscillating knife cutters have transformed corrugated box production. Their precision makes them ideal for intricate designs and logos. This capability enhances brand presentation on packaging.

These cutters are perfect for custom packaging solutions. Their flexibility allows quick design changes, meeting diverse client needs. This is especially beneficial for businesses requiring varied packaging styles.

Automation in digital cutters aids efficient production. They’re capable of short and long runs with consistent quality. Here’s where they particularly excel:

- Custom Designs: Facilitate unique branding.

- Variable Production Runs: Adaptable to different scales.

- Quick Prototyping: Speedy design testing.

By integrating these cutters, manufacturers can efficiently produce high-quality, tailored boxes. This meets growing market demands for personalized and effective packaging solutions.

Enhancing Efficiency and Customization in Packaging

Digital oscillating knife cutters boost packaging efficiency. Their speed and precision reduce production time. This allows manufacturers to meet tight deadlines with ease.

Customization is another significant advantage. These machines enable quick changes to designs. Manufacturers can offer personalized packaging without slowing down operations. This adaptability is crucial in today’s competitive market.

Automation in digital cutters leads to consistent quality. They minimize errors, ensuring each piece matches the design specifications. Benefits include:

- Rapid Prototyping: Test new designs quickly.

- Flexible Production: Easily switch between projects.

- High Consistency: Maintain uniform quality.

Incorporating these cutters into production lines enhances workflows. Businesses can satisfy customer demands while maintaining high standards.

Environmental and Cost Benefits

Digital oscillating knife cutters are environmentally friendly. They eliminate the need for physical dies, reducing material waste. This sustainable approach aligns with the industry’s move towards eco-friendly practices.

Cost savings are another major benefit. These machines lower material usage and labor costs. The setup time is drastically reduced, allowing for cost-efficient production runs.

Key advantages include:

- Waste Reduction: Minimize excess material usage.

- Lower Labor Costs: Less manual intervention needed.

- Reduced Setup Time: Faster transitions between jobs.

Overall, integrating digital cutting technology offers packaging companies significant savings. This efficiency translates to better margins and a stronger competitive position.

Environmental and Cost Benefits

Selecting an ideal digital cutting machine requires careful consideration. Key factors include material types and production volumes. Different machines have various strengths, suited for specific tasks.

Evaluate the software compatibility. Seamless integration into existing workflows is crucial. Choose machines that work with current design software for efficiency.

Consider these essential features:

- Versatility: Ability to handle multiple materials.

- Ease of Use: Simplified operation and maintenance.

- Software Integration: Compatibility with design tools.

Prioritize scalability. Ensure the machine supports future growth. This investment can future-proof your operations, aligning with industry advances.

Future Trends in Digital Cutting Technology

Digital cutting technology continues to evolve rapidly. Innovations are shaping the future of packaging production. Key trends include increased automation and improved AI integration.

Future advancements expected in digital cutting technology:

- Enhanced AI: For better decision-making.

- Sustainability: Improved materials and processes.

- Advanced Sensors: For greater precision.

These trends promise even more efficiency and flexibility. Staying updated ensures businesses remain competitive and adaptable.

Conclusion

Digital oscillating knife cutters are transforming packaging production. They offer precision, flexibility, and efficiency. By adopting this technology, companies gain competitive advantages.

These machines enhance customization and sustainability. They reduce waste and support rapid prototyping. Embracing digital cutting solutions positions manufacturers at the forefront of innovation. As packaging demands evolve, such investments become crucial for staying ahead.