- +1 (904)-532-4333

- huayaotech@gmail.com

Advantages of Oscillating Knife Cutting Machines

- Home

- Blog Archive

- Advantages of Oscillating Knife Cutting Machines

- John Doe

- May 26, 2024

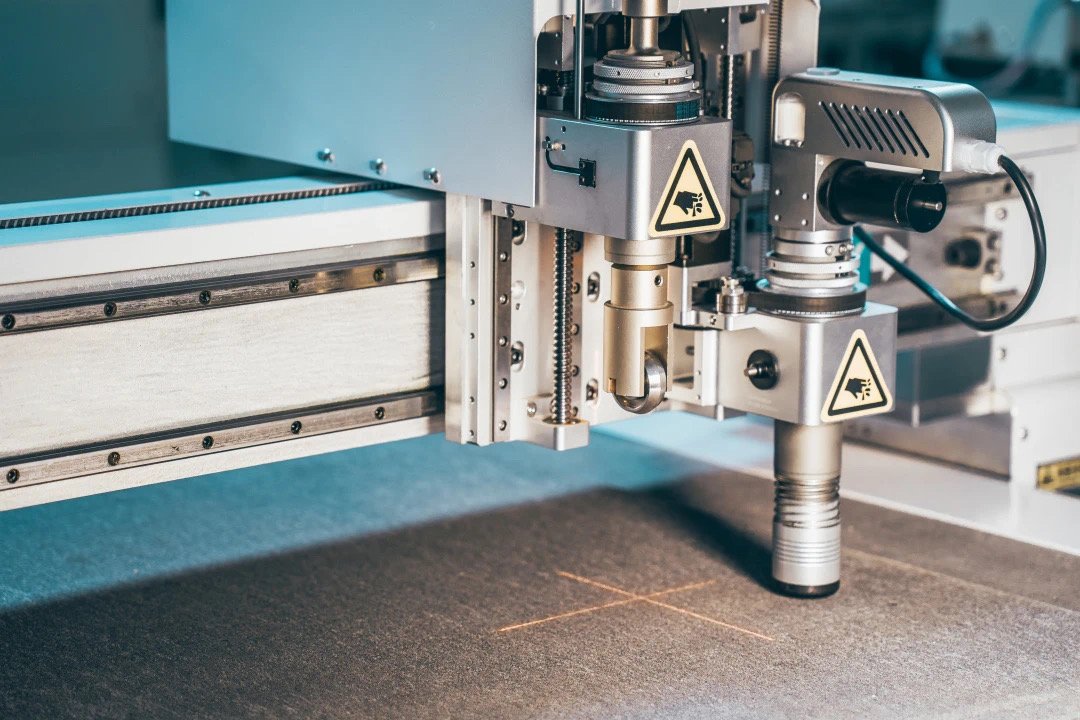

An oscillating knife cutting machine is a type of CNC (Computer Numerical Control) equipment that achieves material cutting through the rapid back-and-forth motion of a blade. This oscillating motion allows the blade to penetrate various materials easily without excessive pressure, reducing the risk of damage to both the material and the machine.

In the field of precision cutting, oscillating knife cutting machines stand out as the top choice for numerous industries. Taking Huayao’s oscillating knife cutting machines as an example, these devices, renowned for their precision and versatility, are reshaping how enterprises approach cutting tasks through technological innovation. This article explores the advantages of using such machines and why they might be the ideal choice for your business.

Precision and Accuracy

Huayao’s oscillating knife cutting machines use high-frequency technology. The blade vibrates up and down 12,000 to 18,000 times each minute. Combined with servo motor drive and CNC systems, they achieve a cutting accuracy of ±0.05mm. Whether for complex patterns on leather products, curved contours of automotive interiors, or precision components made of carbon fiber composites, they avoid burrs and stretching deformation caused by traditional cutting. For example, in cutting aerospace gaskets, Huayao equipment perfectly replicates CAD design drawings, boosting the qualified product rate to over 99%.

Benefits in Various Industries

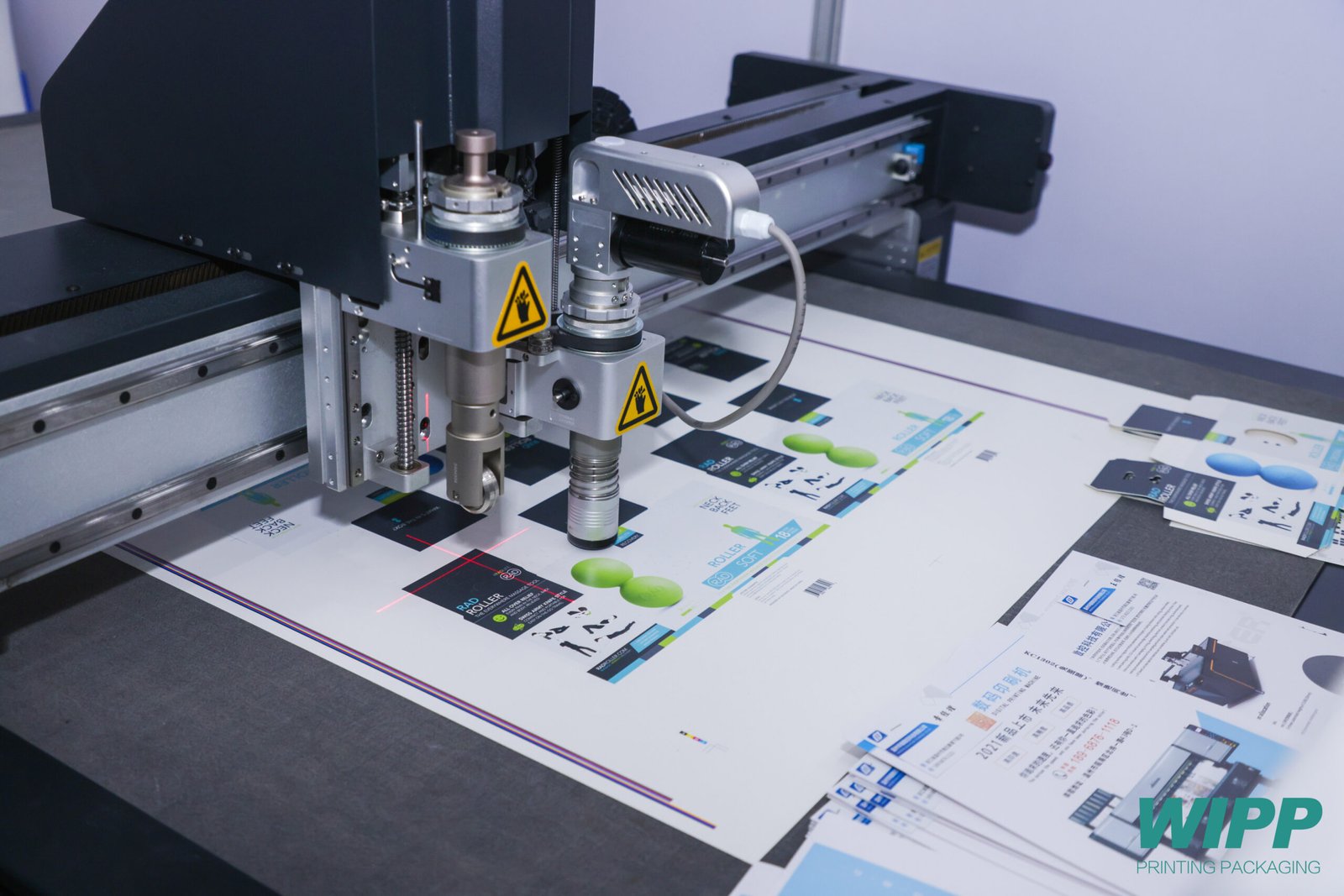

A. Packaging Industry

In the packaging sector, Huayao’s precise cutting ensures that cartons and other packaging materials fit perfectly, reducing the risk of damage during transportation and handling. For rigid materials such as corrugated paper and PVC boards, the pulse cutting of the oscillating knife avoids the charred edges caused by laser cutting, making it ideal for proofing special-shaped boxes in the packaging industry and shortening the sample production cycle by 50%.

B. Advertising & Signage Industry

Huayao’s customized equipment for the advertising field is equipped with visual positioning CCD cameras to support realtime image calibration, enabling complex processes like hollow cutting of 3M reflective film billboards. When cutting flexible light box fabrics, the high-frequency oscillating blade reduces material stretching deformation by 40% compared with traditional processes, ensuring smooth and burr-free edges on sign products.

C. Automotive Interior Industry

In automotive interior production, Huayao’s equipment provides stable support for complex material cutting through its advanced zoned adsorption function. The intelligent zoned adsorption system divides the worktable into multiple independently controllable areas, which can precisely match the adsorption force of each area according to the size and shape of interior materials such as leather, foam, and composite materials. When cutting irregular components like automotive seat foam, the system effectively prevents material displacement or wrinkling during high-frequency cutting, ensuring smooth cutting edges and precise dimensions. Additionally, the equipment can be assisted by a CCD visual positioning system to further enhance the cutting accuracy of special-shaped components, significantly improving efficiency and yield in mass production compared to traditional manual cutting.

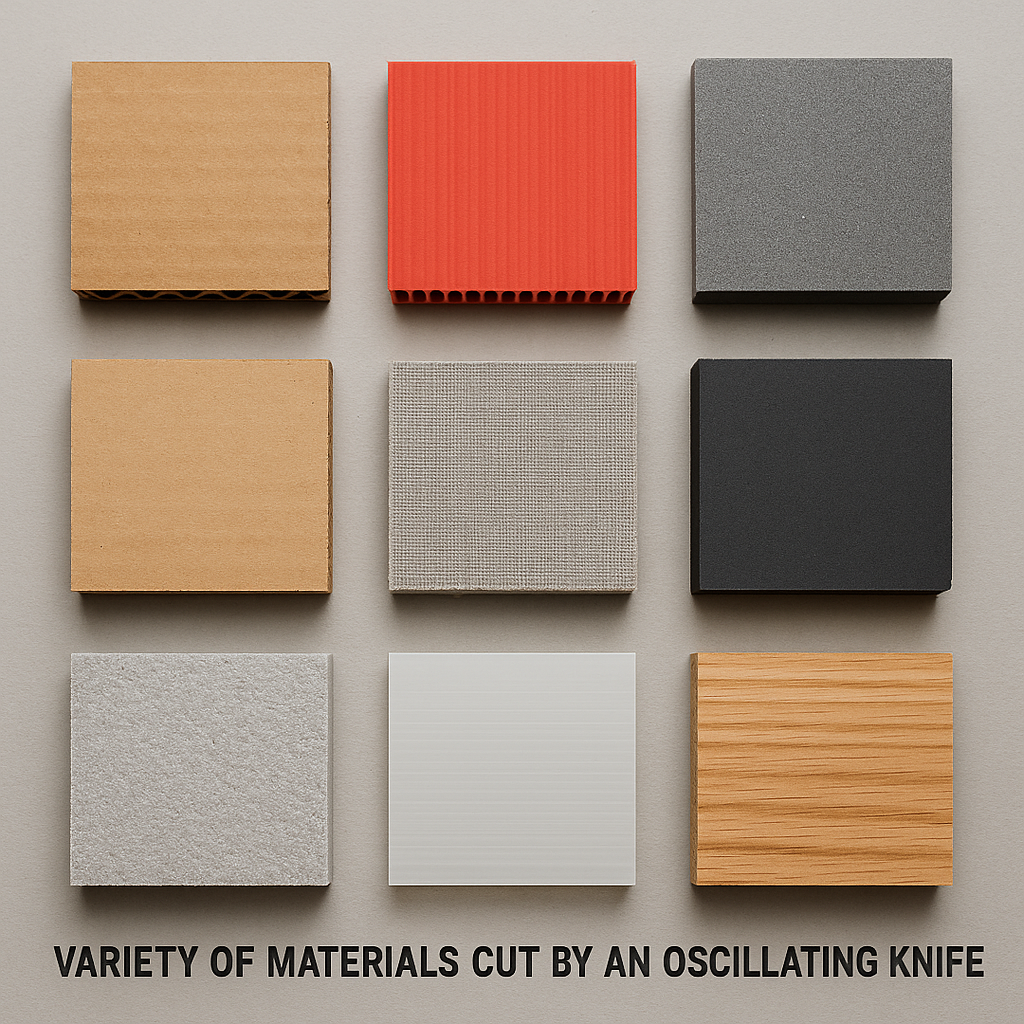

Versatility Across Materials

Another major advantage of oscillating knife cutting machines is their versatility. These machines can cut a wide range of materials, including:

- Cardboard

- Foam

- Rubber

- Gaskets

- Plastics

- Leather

- Fabric

- etc.( Contact Us for More Information) https://huayaocnctech.com/contact/

This versatility makes them suitable for various industries, from light industry (e.g., leather goods, packaging) to heavy manufacturing. The ability to switch between materials without needing significant reconfiguration saves time and increases productivity.

Customization and Flexibility

Oscillating knife cutting machines are also highly customizable. Businesses can easily adjust the machine settings to accommodate different materials and thicknesses. This flexibility allows for tailored solutions that meet specific production needs, making these machines a valuable asset for custom projects.

Speed and Efficiency

The speed of an oscillating knife cutting machine is another significant benefit. The rapid oscillation of the knife allows for fast cutting, reducing production time. This speed does not compromise the quality of the cut, meaning businesses can produce high-quality products quickly.

Increased Output

With faster production times, businesses can increase their output without sacrificing quality. This efficiency can lead to higher profits and a better return on investment for companies investing in oscillating knife technology.

Reduced Material Waste

Due to their precision and accuracy, oscillating knife cutting machines significantly reduce material waste. By cutting materials exactly as needed, businesses can make the most of their resources. This not only saves money but is also an environmentally friendly approach, as it reduces the overall material consumption.

User-Friendly Operation

Many oscillating knife cutting machines are designed with user-friendly interfaces. This makes them easy to operate, even for those who may not be highly skilled in CNC technology. The ease of use minimizes the learning curve and allows businesses to integrate these machines into their production processes quickly.

Training and Support

Huayao provides comprehensive training and technical support services for oscillating knife cutting machines: within China, we can dispatch personnel to any region for on-site training based on customer needs. For overseas clients, we primarily offer remote technical guidance for these machines. If on-site support is required, the client shall reimburse the travel expenses and related costs for our personnel dispatched abroad.

Cost-Effectiveness

While the initial investment in an oscillating knife cutting machine can be significant, the long-term benefits often outweigh the costs. The efficiency, precision, and versatility of these machines lead to cost savings in material use, labor, and production time. Over time, businesses can see a significant return on their investment.

Long-Term Savings

By reducing waste, speeding up production, and minimizing errors, oscillating knife cutting machines can lead to substantial savings. These savings can then be reinvested into the business, promoting growth and innovation.

Conclusion

Oscillating knife cutting machines from Wenzhou Huayao offer numerous advantages that can greatly benefit a wide range of industries. Their precision, versatility, speed, and efficiency make them an excellent investment for businesses looking to improve their production processes. Whether you are in packaging, automotive, textiles, or other industries, these machines from Wenzhou Huayao can help you achieve high-quality results with less waste and lower costs.

In today’s competitive market, staying ahead means investing in technology that enhances productivity and quality. Oscillating knife cutting machines from Wenzhou Huayao provide the tools necessary to meet these demands, making them a smart choice for forward-thinking businesses.

Share this post :

Recent Post

Transform Your Ideas into Reality

Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Quick Links

Applications

- Packaging Industry

- Sign & advertising

- Leather Goods

- Apparel

- Automotive upholstery

- New Energy

Information

huayaotech@gmail.com

+1 (904)-532-4333

+86 189 6876 1117

No.6, Qifeng Rd, Nanbaixiang, Wenzhou, Zhejiang, China

Apex © 2024 All Rights Reserved by FoxCreation

Privacy Policy

Terms & Service